Go to Section

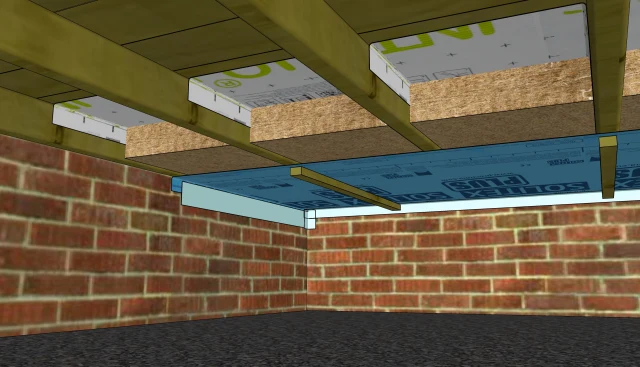

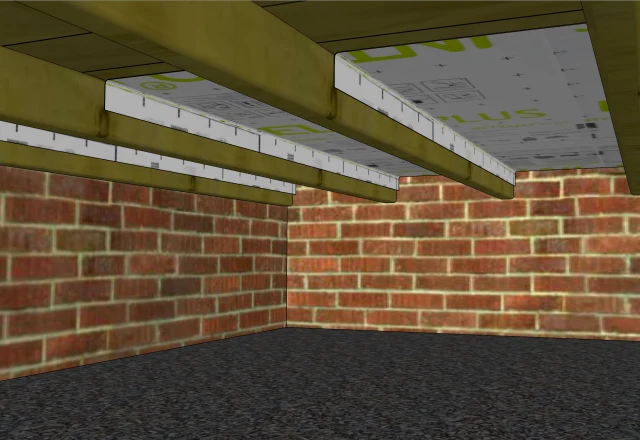

Suspended Timber Floor Insulation: From Underneath Installation Guide (Method 2)

Tuesday 22nd March 2022

Also in category: Airtight and windtight, House insulation, Retrofit

In our other blog posts on how to insulate a suspended timber floor, we described "Method 1", where the floorboards and skirting boards are removed. As it is not always possible to remove the floor coverings and floorboards, we have developed a second method in which insulation and the airtightness products are installed from underneath. All you need is access to the crawl space and enough room under there to complete the installation.

Blog author

Dave Judd

Technical Specification Advisor (BSc Hons, MSc)

Dave has extensive experience with energy efficiency retrofits and is well acquainted with the “fabric first” principles of integrating airtightness and insulation in both new-build and existing buildings. He has also worked within the domestic renewable energy sector, with the main emphasis on solar PV, solar thermal and biomass systems. He has a Degree in Environmental Science and an MSc in Architecture: Advanced Environment & Energy Studies and recently qualified as a Certified Passive House Tradesperson with the Passive House Institute. Outside of work, Dave enjoys trail running and cycling, growing vegetables and being sociable.